WHY PACKAGING MATTERS..

Ready Meals Market Analysis

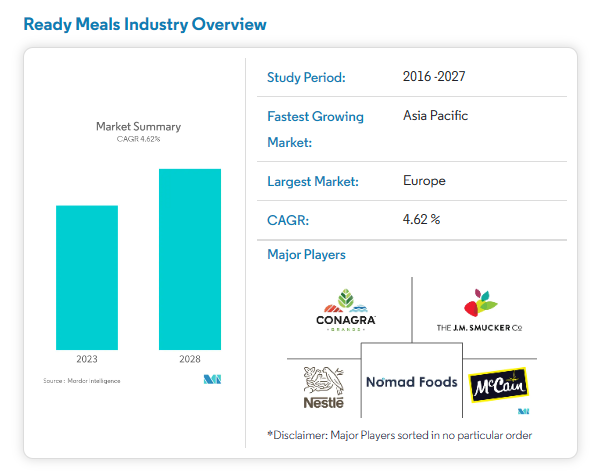

The Ready Meals Market is projected to record a CAGR of 4.62% over the next five years. (reference: Mordor Intelligence)

There are many factors contributing to this growth, including more people working in full-time jobs, back to commuting & travelling post-covid times, signs of people eating out less due to disposable incomes decreasing due to cost of living increases, and the general rapid pace of daily life for many making Healthy Ready-To-Eat meals more appealing.

While the Western World is the greatest consumer of these products, this trend has spread Globally over the last decade, and there’s no sign of it slowing down any time soon.

IS PACKAGING IMPORTANT? Packaging design is crucial for these products. The majority of purchase decisions are made in-store on the spur of the moment, and as such packaging plays an important role in the decision-making process.

The major factor driving the market is the convenience provided in terms of time-saving, less effort of cooking, and ease of handling and storage.

Using Packaging to Emphasise Freshness:

One factor that convinces consumers to buy a ready-to-eat meal product is presentation.

You can use creative packaging design to sell taste, enhance freshness cues, and to preserve the products’ shelf-life. One tool packaging designers frequently use are peep windows. Windows allow the customer to view the food they’re buying but in a way that maximises the appeal – showcasing only the best of the product.

This works well for products that are whole and ready to eat, but with long shelf life foods or partly cooked items – such as microwavable meals – packaging designers often need to use images and text to grab the customer’s imagination and attention instead.

The Importance of Functionality:

With packaging, functionality is just as much of a concern as design and aesthetics: not only to ensure its contents stay fresh and protected, but for ready-to-eat products the packaging also needs to function as a dish to cook with and eat from, so packaging materials need to be carefully selected to ensure that they deliver on all levels.

Environmentally Friendly Packaging:

While the ready-to-eat and convenience food markets continue to increase in popularity, people will come to expect more and more out of their RTE packaging, not just in freshness and functionality but also in the materials they use. LPS have a range of environmentally friendly packaging, from Paperboard Trays to Pulp-Pro Trays.

Modern Packaging Solutions from LPS:

The ALX Heat Sealing System has been created for take-away solutions and supports the sales of hot, chilled and deep frozen meals by using a reliable thermo-electric technique for sealing film/foil onto trays, such as:

- CPET trays for use in the Oven & Microwave

- Environmentally Friendly Paperboard Trays for use in Oven & Microwave

- Environmentally Friendly Pulp-Pro Trays for use in Microwave

- Cardboard Take-Away Boxes for use in Microwave

Once sealed, the product is guaranteed to be leak proof and aroma tight. Consumers can then easily peel off the covering film/foil and then enjoy the meal. The patented machines are easy to use, also economic for small volume businesses – so we are proud to be able to say – this is an investment that will give you benefits for many years.

We have a large variety of products in stock, available for Next Day Delivery in the UK (minimum order is 1 box only!)

The PERFECT take-away system from LPS.

Contact us to see how we can help with your Packaging Solutions!

Click here to view Packaging Shop.